Did you know that the global meat processing market is projected to reach over $700 billion by 2025? That’s not just a staggering figure; it reflects the fierce competition and evolving dynamics within the industry. The “Meat Processing Plant Competition Study” aims to shed light on these competitive forces, offering a deeper understanding of what drives success in this sector. At its core, this study focuses on analyzing the various factors that influence competition among meat processing plants, from technological advancements to market trends.

- The meat processing industry is rapidly evolving, influenced by consumer preferences and technological innovations.

- Understanding competition is crucial for meat processing plants to thrive.

- Market dynamics impact profitability and operational efficiency.

- Technological advancements are reshaping production processes.

- Regulatory challenges are a significant concern for the industry.

- Sustainability practices are becoming increasingly important.

- Consumer demand for quality and safety drives competition.

- Supply chain management plays a vital role in operational success.

- Strategic location can provide a competitive edge.

- Continuous improvement is essential for long-term viability.

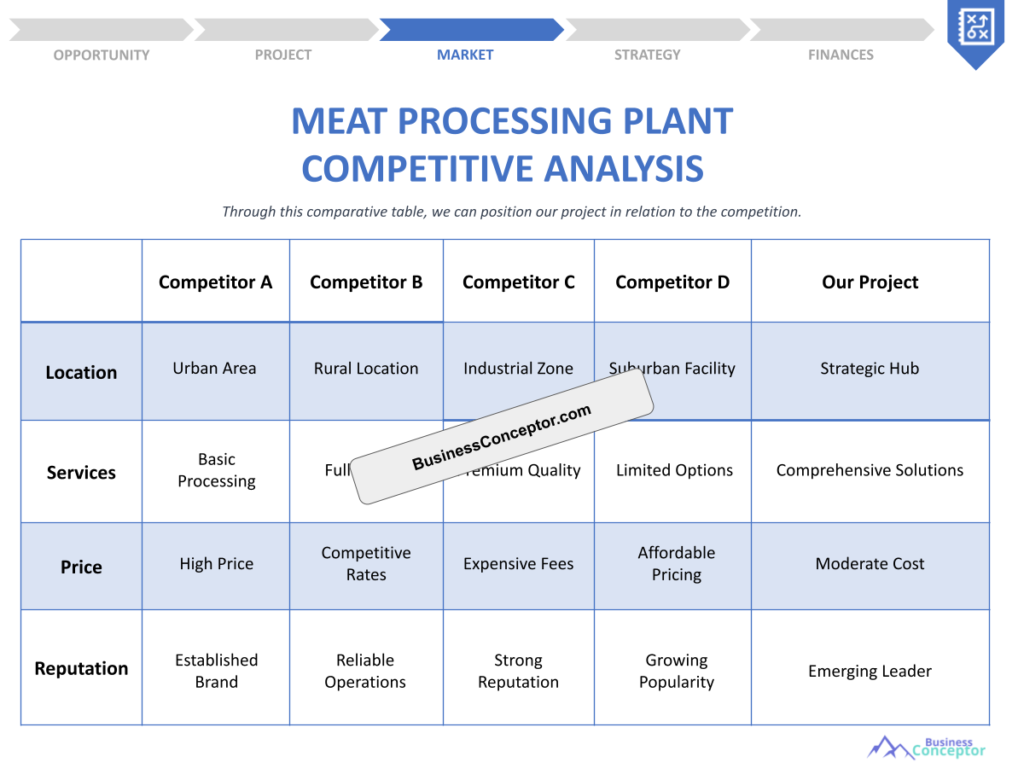

Competitive Landscape in Meat Processing

The meat processing industry is characterized by a highly competitive environment. Companies must navigate various challenges, including market saturation and evolving consumer preferences. Analyzing the competitive landscape helps identify key players and strategies that lead to success. For instance, larger meat processing plants often benefit from economies of scale, allowing them to lower costs and increase profitability. On the other hand, smaller plants may focus on niche markets, offering specialized products that cater to specific consumer needs. Understanding these dynamics is crucial for new entrants and existing players alike.

As competition intensifies, companies must continuously adapt and innovate. This section sets the stage for exploring the factors that influence competition in greater detail. In this fast-paced industry, being aware of the trends and shifts in consumer behavior is vital for survival. The ability to pivot and adjust strategies based on real-time data can make the difference between thriving and merely surviving.

| Factor | Description |

|---|---|

| Market Size | Large and growing |

| Key Players | Major corporations and local firms |

| Consumer Trends | Demand for quality and sustainability |

- Market saturation increases competition

- Technological advancements create new opportunities

- Regulatory compliance is critical for success

- "In a competitive landscape, adaptability is key."

Market Trends and Innovations

The meat processing industry is not static; it evolves with changing market trends and innovations. From plant-based alternatives to automation in processing, these trends shape how companies operate and compete. This section will explore current trends that are redefining the industry. For example, the rise of plant-based diets has led many meat processing plants to diversify their offerings, incorporating alternative protein sources. Additionally, automation and robotics are enhancing efficiency, reducing labor costs, and improving product consistency. These innovations not only boost productivity but also help companies stay competitive.

By recognizing and adapting to these trends, meat processing plants can position themselves favorably in the market, ensuring their relevance and profitability. For instance, companies that embrace sustainability initiatives are likely to attract a growing segment of environmentally conscious consumers. Moreover, leveraging technology for data analytics can provide insights into consumer preferences and operational efficiencies, allowing for better decision-making.

- Embrace plant-based product lines

- Invest in automation technologies

- Focus on sustainability initiatives

- The above steps must be followed rigorously for optimal success.

Regulatory Challenges in Meat Processing

Navigating the regulatory landscape is a critical aspect of operating a meat processing plant. Regulations concerning food safety, labeling, and environmental impact can significantly affect operations. Understanding these regulations helps companies mitigate risks and maintain compliance. For instance, the USDA and FDA impose strict guidelines on meat processing, ensuring that products are safe for consumption. Non-compliance can lead to severe penalties and damage to a company’s reputation. Moreover, environmental regulations are becoming stricter, prompting companies to adopt sustainable practices to minimize their ecological footprint.

This section emphasizes the importance of staying informed about regulatory changes and adapting practices accordingly to avoid potential pitfalls. Companies that proactively engage with regulatory bodies and invest in compliance training for their staff are more likely to succeed in this complex environment. Additionally, fostering a culture of safety and compliance within the organization can lead to improved operational performance.

- Regulatory compliance is essential for market access

- Non-compliance can lead to fines and reputational damage

- Sustainability practices can enhance compliance and public perception

- "Compliance is not just a requirement; it’s a competitive advantage."

Consumer Preferences and Quality Control

Understanding consumer preferences is vital for meat processing plants to thrive. Today’s consumers are more informed and concerned about the quality and safety of the products they purchase. This section delves into how companies can align their offerings with consumer expectations. Quality control is paramount in the meat processing industry. Implementing rigorous quality assurance protocols ensures that products meet safety standards and consumer expectations. For example, traceability systems allow consumers to know the origin of their meat, building trust and loyalty.

By prioritizing quality and transparency, meat processing plants can differentiate themselves in a crowded market, appealing to health-conscious consumers. Additionally, companies that actively seek feedback from their customers can gain valuable insights into preferences, leading to improved products and services. This engagement fosters a sense of community and loyalty, which is essential in today’s competitive landscape.

| Preference | Importance Level |

|---|---|

| Quality Assurance | High |

| Transparency | Increasing |

| Sustainability | Growing concern |

- Implement quality control measures

- Enhance product transparency

- Adapt to shifting consumer demands

- "To succeed, always move forward with a clear vision."

Supply Chain Management in Meat Processing

Effective supply chain management is crucial for meat processing plants to maintain efficiency and profitability. From sourcing raw materials to distribution, each step of the supply chain must be optimized for success. This section explores the intricacies of supply chain management in the meat processing industry. A well-structured supply chain can help mitigate risks associated with disruptions, such as natural disasters or market fluctuations. For instance, establishing strong relationships with suppliers ensures a consistent flow of high-quality raw materials. Additionally, leveraging technology for inventory management can reduce waste and improve overall efficiency.

By focusing on supply chain optimization, meat processing plants can enhance their competitive edge and respond more effectively to market demands. This can involve adopting just-in-time inventory practices, investing in logistics technology, and utilizing data analytics for demand forecasting. Companies that excel in these areas are better positioned to adapt to changes in consumer preferences and market conditions.

- Strong supplier relationships enhance reliability

- Technology improves inventory management

- Risk mitigation strategies are essential

Economic Impact of Meat Processing Plants

The economic impact of meat processing plants extends beyond their operations. These facilities contribute significantly to local economies by creating jobs, supporting agriculture, and generating tax revenue. This section examines the broader economic implications of the meat processing industry. For example, a single meat processing plant can create hundreds of jobs, benefiting local communities and economies. Additionally, these plants often rely on local farmers for their raw materials, supporting the agricultural sector and promoting sustainable practices.

Understanding the economic contributions of meat processing plants underscores their importance in the overall landscape, highlighting the need for continued investment and support. Furthermore, the presence of these plants can lead to improved infrastructure and services in rural areas, making them more attractive for future investments. By recognizing the economic value of the meat processing industry, stakeholders can advocate for policies that support its growth and sustainability.

| Contribution | Impact Level |

|---|---|

| Job Creation | High |

| Support for Farmers | Significant |

| Tax Revenue | Essential |

- Job creation supports local economies

- Collaboration with farmers fosters sustainability

- Economic contributions enhance community well-being

- "Success comes to those who persevere."

Strategic Recommendations for Success

To succeed in the competitive meat processing landscape, companies must adopt strategic recommendations that address current challenges and opportunities. This section outlines actionable strategies for meat processing plants to enhance their competitive position. For instance, diversifying product lines to include healthier options can attract a broader customer base. Additionally, investing in technology for automation can streamline operations and reduce costs, ultimately leading to increased profitability.

By implementing these strategies, meat processing plants can navigate the competitive landscape more effectively, ensuring long-term success. Moreover, fostering a culture of innovation within the organization can lead to new ideas and improvements that further enhance competitiveness. Continuous training and development for employees can also drive efficiency and productivity, making the entire operation more robust.

- Diversify product offerings

- Invest in technology and automation

- Focus on sustainability and compliance

Future Outlook for Meat Processing Plants

The future of meat processing plants is shaped by various factors, including consumer trends, technological advancements, and regulatory changes. This section explores the anticipated developments that will influence the meat processing industry in the coming years. As consumer preferences continue to shift towards healthier and more sustainable options, meat processing plants must adapt to meet these demands. Furthermore, advancements in technology, such as artificial intelligence and blockchain, are expected to enhance efficiency and transparency in operations.

By staying ahead of these trends, meat processing plants can position themselves for success in an ever-evolving market. Companies that embrace innovation and sustainability will likely attract a loyal customer base, while those that resist change may struggle to remain relevant. The integration of technology into production processes not only improves efficiency but also provides valuable data that can inform strategic decisions, ensuring long-term viability in a competitive landscape.

| Trend | Expected Impact |

|---|---|

| Healthier Options | Increased demand |

| Technology Adoption | Enhanced efficiency |

| Sustainability Focus | Improved public perception |

- Monitor consumer trends regularly

- Embrace technological innovations

- Prioritize sustainability initiatives

Key Takeaways and Recommendations

As we conclude this comprehensive analysis of the meat processing plant competition study, several key takeaways emerge. Understanding the competitive landscape, consumer preferences, and regulatory challenges is essential for success in this industry. Practical advice includes focusing on quality control, optimizing supply chains, and embracing innovation. These strategies will not only enhance operational efficiency but also improve competitiveness in a crowded market.

By applying these insights, meat processing plants can navigate challenges and seize opportunities, paving the way for a successful future. Continuous adaptation and a proactive approach to market changes will be critical for companies aiming to thrive in this dynamic environment. Ultimately, those who remain committed to excellence and innovation will lead the way in the meat processing industry.

- "Success comes to those who persevere."

- Analyze the competitive landscape regularly.

- Adapt to consumer preferences swiftly.

- Invest in technology and innovation.

Conclusion

In summary, the meat processing plant competition study reveals a complex and dynamic industry landscape. By understanding the competitive forces at play and implementing strategic recommendations, meat processing plants can thrive in this challenging environment. Now is the time to take action—whether that means investing in technology, diversifying product lines, or enhancing sustainability efforts.

For those looking to establish a successful operation, consider utilizing the Meat Processing Plant Business Plan Template. This resource can provide valuable guidance as you navigate the complexities of launching your plant.

Additionally, explore our articles for further insights into the meat processing industry:

- Article 1: SWOT Analysis for Meat Processing Plant: Ensuring Business Success

- Article 2: Meat Processing Plant Profitability: What You Need to Know

- Article 3: Developing a Business Plan for Your Meat Processing Plant: Comprehensive Guide

- Article 4: Financial Planning for Meat Processing Plants: A Detailed Guide with Examples

- Article 5: Launching a Meat Processing Plant: Complete Guide with Example

- Article 6: Building a Marketing Plan for Your Meat Processing Plant (+ Example)

- Article 7: Creating a Business Model Canvas for a Meat Processing Plant: Examples and Tips

- Article 8: How Much Does It Cost to Start a Meat Processing Plant?

- Article 9: Meat Processing Plant Feasibility Study: Essential Guide

- Article 10: Meat Processing Plant Risk Management: Comprehensive Strategies

- Article 12: Meat Processing Plant Legal Considerations: Expert Analysis

- Article 13: Meat Processing Plant Funding Options: Comprehensive Guide

- Article 14: Meat Processing Plant Growth Strategies: Scaling Success Stories

FAQ Section

What is a meat processing plant competition study?

A meat processing plant competition study involves analyzing the competitive landscape of the meat processing industry, focusing on market trends, challenges, and opportunities.

Why is understanding competition important in meat processing?

Understanding competition helps meat processing plants identify strategies to improve efficiency, profitability, and market positioning.

What are current trends in the meat processing industry?

Current trends include the rise of plant-based alternatives, increased automation, and a focus on sustainability.

What regulations impact meat processing plants?

Meat processing plants must comply with food safety regulations set by agencies like the USDA and FDA, as well as environmental regulations.

How can consumer preferences affect meat processing?

Consumer preferences for quality and sustainability drive meat processing plants to adapt their offerings and practices to meet demand.

What role does supply chain management play in meat processing?

Effective supply chain management ensures a consistent flow of quality raw materials, reducing costs and enhancing efficiency.

What are the economic impacts of meat processing plants?

Meat processing plants contribute to local economies by creating jobs, supporting agriculture, and generating tax revenue.

What strategies can meat processing plants implement for success?

Strategies include diversifying product lines, investing in technology, and prioritizing sustainability.

What is the future outlook for the meat processing industry?

The future is likely to see increased demand for healthier options, greater technological adoption, and a focus on sustainability.

How can meat processing plants enhance their competitiveness?

By understanding market dynamics, adapting to consumer preferences, and implementing innovative practices, meat processing plants can improve their competitive position.