Did you know that the concrete block manufacturing industry generates billions in revenue every year? It’s a massive market, yet many entrepreneurs overlook the competitive dynamics that can make or break their businesses. Concrete Block Manufacturing Competition Study dives into the heart of this industry, revealing strategies and insights that can help you thrive. In this article, we’ll explore the competitive landscape, emerging trends, and practical tips for standing out in the concrete block manufacturing sector.

- Understanding the competitive landscape of concrete block manufacturing.

- Key factors affecting market share in the industry.

- Strategies for differentiating your concrete block products.

- Importance of sustainability in manufacturing.

- Innovations shaping the future of concrete blocks.

- Cost-effective production techniques.

- Quality control measures in concrete manufacturing.

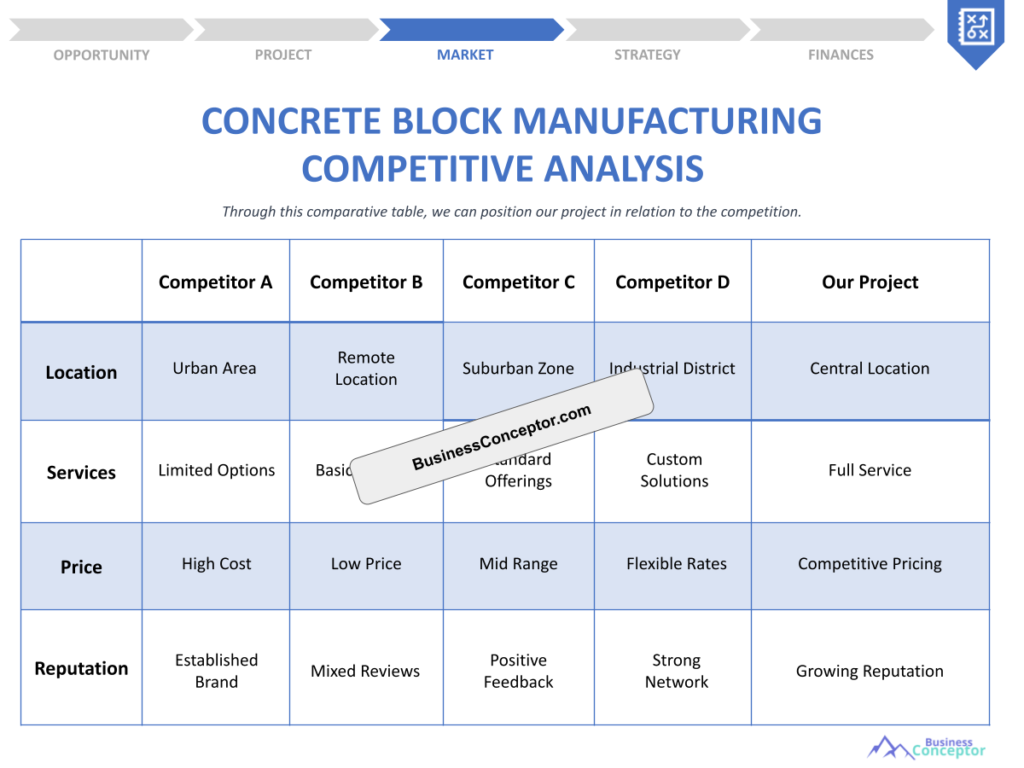

- Analyzing competitor strengths and weaknesses.

- Market entry strategies for new businesses.

- The role of technology in enhancing production efficiency.

Understanding the Competitive Landscape

The concrete block manufacturing industry is incredibly competitive, with numerous players vying for market share. Understanding the competitive landscape is crucial for any business looking to enter or expand in this market. By analyzing competitors, you can identify opportunities and threats that may affect your business strategy.

For instance, consider two manufacturers: one focusing on high-quality, eco-friendly blocks and the other on low-cost production. Both have different target markets and strategies, impacting their market presence. A thorough analysis of such competitors can reveal what works and what doesn’t in your approach.

In summary, recognizing the competitive landscape enables you to formulate effective strategies that can position your company for success. This understanding will serve as a foundation for exploring further sections about market trends and innovations.

| Key Insights | Description |

|---|---|

| Market Competition | Overview of major players in the market |

| Competitive Strategies | Different approaches used by competitors |

- Analyze competitors’ strengths and weaknesses

- Identify market gaps and opportunities

- Develop a unique selling proposition…

“Success is not the key to happiness. Happiness is the key to success.” – Albert Schweitzer

Key Factors Affecting Market Share

Several key factors influence market share in the concrete block manufacturing industry. Understanding these factors can help you navigate the competitive landscape more effectively. Factors such as pricing, quality, and customer service play a significant role in how consumers perceive your products.

For example, a study showed that companies offering superior customer service gained a 20% higher market share compared to their competitors. This statistic highlights the importance of not just the product but also the experience you provide to your customers. If you can deliver an exceptional customer experience alongside quality concrete blocks, you will likely stand out in a crowded market.

Recognizing these key factors will prepare you for the next section, where we’ll discuss actionable steps to improve your market share.

- Assess competitor pricing strategies.

- Invest in quality control processes.

- Enhance customer service and support.

The above steps must be followed rigorously for optimal success.

Innovations in Concrete Block Manufacturing

Innovation is at the heart of successful concrete block manufacturing. Companies that invest in new technologies and processes often gain a competitive edge. This section will explore some of the latest innovations transforming the industry.

For instance, the introduction of automated production lines has significantly increased efficiency and reduced labor costs. Companies that have adopted such technologies often report a substantial increase in output and a decrease in production time. Additionally, innovative materials, like eco-friendly concrete, are becoming more prevalent, allowing manufacturers to appeal to a broader audience.

By embracing innovation, manufacturers can not only enhance their operational efficiency but also improve product quality. This sets the stage for our next section, which will cover sustainability practices in the industry.

- Automation in production processes

- Use of recycled materials

- Innovations in design and functionality…

“Innovation distinguishes between a leader and a follower.” – Steve Jobs

Sustainability in Concrete Block Production

Sustainability has become a crucial aspect of concrete block manufacturing. Consumers are increasingly seeking eco-friendly products, making it essential for manufacturers to adopt sustainable practices. This section will discuss the benefits of going green in your production processes.

For example, companies that utilize recycled materials in their blocks not only reduce waste but also appeal to environmentally-conscious consumers. Studies show that businesses prioritizing sustainability often enjoy a loyal customer base willing to pay a premium for eco-friendly products. Additionally, implementing energy-efficient processes can significantly lower operational costs, further enhancing profitability.

Integrating sustainable practices is not just good for the planet; it’s also good for business. This leads us to the next section, where we will examine quality control measures that can enhance product reliability.

| Sustainability Practices | Benefits |

|---|---|

| Use of recycled materials | Reduces waste and costs |

| Energy-efficient production | Reduces operational costs |

- Implement recycling programs

- Invest in energy-efficient machinery

- Educate staff on sustainable practices…

Quality Control Measures

Quality control is paramount in the concrete block manufacturing industry. Ensuring that your products meet high standards can significantly impact customer satisfaction and brand reputation. This section will explore essential quality control measures.

Implementing rigorous testing procedures, such as compressive strength tests and dimensional accuracy checks, can help identify defects before products reach customers. Companies that prioritize quality often see a reduction in returns and complaints, leading to improved customer loyalty and trust. Moreover, regular training for staff on quality assurance practices can further enhance the effectiveness of these measures.

By establishing a robust quality control system, manufacturers can assure customers of their product reliability. This will set the stage for our next section, where we’ll look into strategic planning for market entry.

| Quality Control Measures | Importance |

|---|---|

| Regular testing protocols | Ensures product reliability |

| Staff training on quality | Reduces defects |

- Develop comprehensive testing procedures

- Train staff on quality assurance

- Monitor product performance…

Strategic Planning for Market Entry

Strategic planning is essential for any business looking to enter the concrete block manufacturing market. A well-thought-out plan can help you navigate challenges and seize opportunities. This section will provide insights into effective market entry strategies.

For instance, conducting thorough market research can reveal valuable insights into customer needs and preferences. By understanding your target audience, you can tailor your offerings to meet their demands, enhancing your chances of success. Additionally, establishing partnerships with local suppliers and builders can help you gain traction in the market more quickly.

Having a clear strategy not only guides your actions but also helps you allocate resources efficiently. This sets up our next section, which will focus on the risks and challenges in the concrete block manufacturing industry.

| Market Entry Strategies | Benefits |

|---|---|

| Comprehensive market research | Informs product development |

| Building partnerships | Expands market reach |

- Identify target markets

- Conduct competitor analysis

- Develop a marketing strategy…

Risks and Challenges in Concrete Block Manufacturing

Entering the concrete block manufacturing industry comes with its share of risks and challenges. Understanding these obstacles is vital for any entrepreneur. This section will outline common risks associated with this sector.

For example, fluctuating raw material prices can significantly impact production costs. Manufacturers must be prepared to adapt their pricing strategies in response to market changes to maintain profitability. Additionally, regulatory compliance issues can arise, requiring businesses to stay updated on local and national regulations to avoid penalties.

Being aware of these risks allows businesses to develop contingency plans, ensuring long-term sustainability. This leads us to our next section, which will explore the importance of customer satisfaction in the concrete block market.

| Risks in Manufacturing | Mitigation Strategies |

|---|---|

| Raw material price volatility | Diversify suppliers |

| Regulatory compliance issues | Stay updated on regulations |

- Monitor market trends

- Establish strong supplier relationships

- Create a risk management plan…

Importance of Customer Satisfaction

Customer satisfaction is the backbone of any successful business, including concrete block manufacturing. Happy customers lead to repeat business and positive word-of-mouth. This section will discuss strategies for enhancing customer satisfaction.

Providing excellent customer service, timely delivery, and high-quality products can significantly improve customer loyalty. Companies that actively seek feedback and make necessary adjustments often see higher satisfaction rates. For example, implementing a customer feedback system can provide insights into areas for improvement, allowing you to address concerns before they escalate.

By prioritizing customer satisfaction, manufacturers can create a loyal customer base that drives growth. This sets the stage for our final section, which will summarize key points and encourage actionable steps.

| Customer Satisfaction Strategies | Impact |

|---|---|

| Responsive customer service | Increases loyalty |

| Quality product guarantees | Builds trust |

- Implement customer feedback systems

- Train staff on customer interaction

- Offer loyalty programs…

Conclusion

In summary, navigating the concrete block manufacturing industry requires a deep understanding of the competitive landscape, key market factors, innovations, and the importance of customer satisfaction. By implementing the strategies discussed in this article, you can position your business for success and sustainability in a dynamic market.

For those looking to take a more structured approach, consider using our Concrete Block Manufacturing Business Plan Template. This resource can help you outline your strategy and enhance your chances of success.

Additionally, check out these articles that provide valuable insights into various aspects of concrete block manufacturing:

- SWOT Analysis for Concrete Block Manufacturing: Achieving Market Success

- Concrete Block Manufacturing Profitability: Tips for Financial Success

- Crafting a Business Plan for Your Concrete Block Manufacturing: Step-by-Step Guide

- How to Create a Financial Plan for Your Concrete Block Manufacturing Business: Step-by-Step Guide (+ Template)

- Starting a Concrete Block Manufacturing Business: A Detailed Guide

- Building a Concrete Block Manufacturing Marketing Plan: Strategies and Example

- Crafting a Business Model Canvas for Concrete Block Manufacturing: Tips and Examples

- How Much Does It Cost to Start a Concrete Block Manufacturing Business?

- Concrete Block Manufacturing Feasibility Study: Essential Guide

- Concrete Block Manufacturing Risk Management: Essential Guide

- Concrete Block Manufacturing Legal Considerations: Ultimate Guide

- Concrete Block Manufacturing Funding Options: Ultimate Guide

- Concrete Block Manufacturing Growth Strategies: Scaling Success Stories

FAQ

What are the main challenges in concrete block manufacturing?

The primary challenges in concrete block manufacturing include fluctuating raw material prices, maintaining quality control, and ensuring compliance with regulations.

How can I improve customer satisfaction in my concrete block business?

To enhance customer satisfaction, focus on providing exceptional customer service, ensuring product quality, and actively seeking feedback from clients.

What innovations are currently shaping the concrete block industry?

Innovations such as automation in production, the use of eco-friendly materials, and advanced quality control measures are key trends transforming the concrete block manufacturing landscape.

How can I conduct effective market research for concrete blocks?

Effective market research can be achieved by utilizing surveys, analyzing competitors, and studying market trends to gather valuable insights into consumer preferences.

What role does sustainability play in concrete block manufacturing?

Sustainability is crucial as it attracts eco-conscious consumers and can lead to reduced production costs through energy-efficient practices and the use of recycled materials.

What are the benefits of using recycled materials in concrete block production?

Using recycled materials lowers costs, minimizes waste, and enhances brand image, making it an attractive option for manufacturers.

How important is quality control in concrete block manufacturing?

Quality control is essential for ensuring product reliability and customer satisfaction, helping to minimize returns and complaints.

What strategies can I use to differentiate my concrete block products?

To stand out, focus on unique features, sustainability, and superior customer service, making your offerings more appealing to consumers.

What are some effective marketing strategies for concrete block manufacturers?

Online marketing, participation in trade shows, and forming partnerships with builders can significantly enhance visibility in the market.

How can I prepare for risks in the concrete block industry?

Developing a risk management plan, diversifying suppliers, and staying informed about market trends can help mitigate potential risks in concrete block manufacturing.