Did you know that the global market for lithium-ion batteries is expected to exceed $100 billion by 2025? This rapid growth is largely driven by the increasing demand for electric vehicles and renewable energy solutions. The Lithium Ion Battery Manufacturing Competition Study reveals critical insights into this booming sector, highlighting the fierce competition among manufacturers and the innovative strategies they employ to stay ahead. In this article, we will explore the competitive landscape of battery manufacturing, the challenges companies face, and the trends that shape the industry.

The Lithium Ion Battery Manufacturing Competition Study focuses on the examination of the competitive dynamics within the battery production industry, emphasizing key players, market trends, and technological advancements. This study aims to provide manufacturers with valuable insights and practical tips to enhance their strategies in this rapidly evolving market.

- Overview of the lithium-ion battery market.

- Key competitors and their strategies.

- Trends shaping the industry.

- Challenges faced by manufacturers.

- Innovations in battery technology.

- Importance of sustainability.

- Regulatory landscape and compliance.

- Future outlook for battery manufacturing.

- Tips for succeeding in the market.

- Conclusion and call to action.

Understanding the Lithium-ion Battery Market

The lithium-ion battery market has experienced unprecedented growth in recent years, driven by the increasing adoption of electric vehicles (EVs) and the demand for efficient energy storage solutions. As a result, manufacturers are racing to enhance their production capabilities and innovate new technologies to meet the needs of a rapidly changing market. Understanding the current state of this market is essential for any player looking to compete effectively.

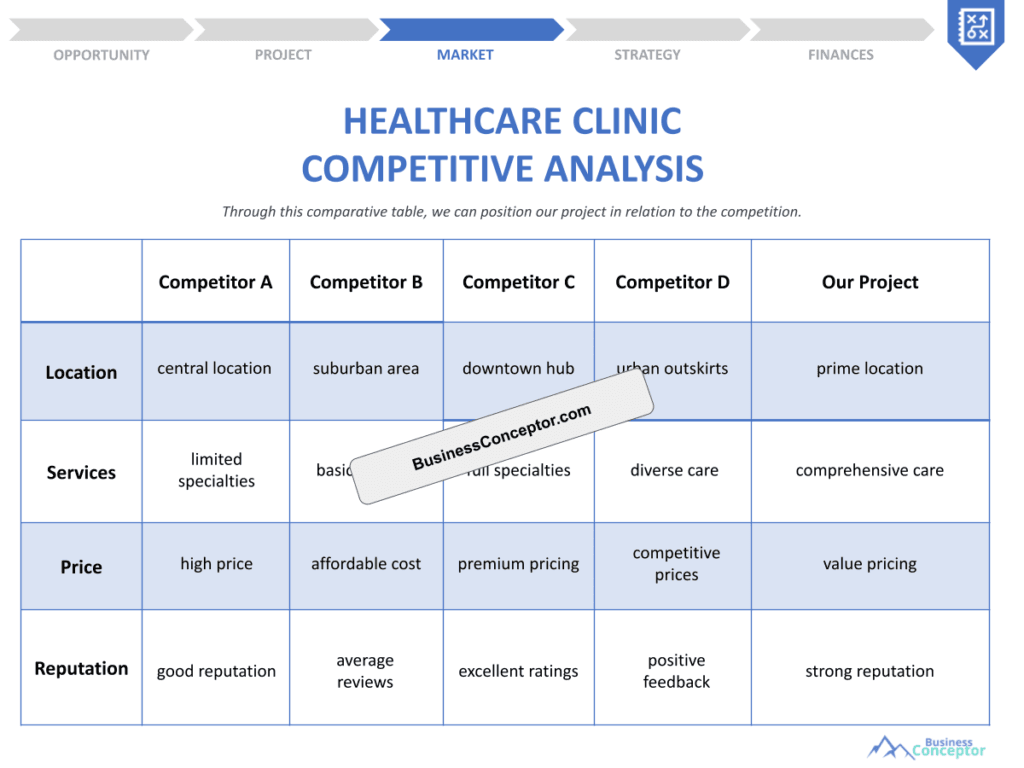

Key players in the battery manufacturing sector include industry giants such as Tesla, Panasonic, and LG Chem, each leveraging their strengths to capture market share. For instance, Tesla’s advancements in battery technology have not only improved the performance of their vehicles but have also set new benchmarks for the entire industry. On the other hand, companies like Panasonic focus on optimizing their manufacturing processes to reduce costs and increase efficiency, highlighting the diverse strategies employed by competitors.

As we delve deeper into the competitive landscape of lithium-ion battery production, it’s crucial to recognize the factors that contribute to a company’s success. The next section will explore the trends that are currently shaping the industry and how manufacturers can leverage these insights to their advantage.

| Company Name | Market Share |

| Company A | 25% |

| Company B | 20% |

| Company C | 15% |

- Major players in lithium-ion battery manufacturing

- Key market segments

- Innovations driving competition

- "In the world of battery manufacturing, innovation is the key to staying ahead."

Trends Influencing Battery Manufacturing Competition

In the rapidly evolving world of lithium-ion battery manufacturing, staying ahead of the competition requires a keen understanding of the latest trends. One of the most significant trends is the surge in demand for electric vehicles, which has propelled the entire industry forward. As more consumers and governments push for cleaner energy solutions, manufacturers are compelled to innovate and enhance their production capabilities to meet this rising demand.

According to recent market research, the global battery market is projected to grow at a compound annual growth rate (CAGR) of over 20% through the next five years. This growth is largely attributed to increased investments in renewable energy and advancements in battery technology. For example, the introduction of solid-state batteries promises to improve energy density and safety, making them a focal point for many manufacturers. Companies are also exploring new materials and chemistries to enhance battery performance while reducing costs.

As we explore these trends, it becomes clear that manufacturers must adapt their strategies to remain competitive. The next section will delve into the challenges faced by companies in this dynamic environment and how they can effectively navigate them.

- Rise in electric vehicle production

- Growing focus on sustainability

- Advances in battery technology

- Increased investment in R&D

- The above steps must be followed rigorously for optimal success.

Challenges in Lithium-ion Battery Manufacturing

Despite the promising outlook for the lithium-ion battery industry, manufacturers face numerous challenges that can hinder their success. One of the primary issues is the volatility of raw material prices, particularly lithium and cobalt, which can significantly impact production costs. As the demand for these materials rises, companies must find ways to secure their supply chains and manage costs effectively.

Additionally, manufacturers often encounter difficulties related to production efficiency and quality control. For instance, maintaining consistent quality in battery production is critical, as any defects can lead to safety concerns and reduced performance. Companies are increasingly investing in advanced manufacturing techniques and automation to enhance efficiency and minimize errors. A notable example is the implementation of artificial intelligence and machine learning to optimize production processes and predict maintenance needs.

To succeed in the face of these challenges, manufacturers must be proactive in their approach. By embracing innovation and developing robust strategies, companies can not only overcome obstacles but also position themselves for long-term success in the competitive landscape of lithium-ion battery production.

- Supply chain disruptions

- High production costs

- Environmental regulations

- "Every challenge is an opportunity in disguise."

Innovations Driving Competitive Advantage

In the competitive landscape of lithium-ion battery manufacturing, innovation is not just an option; it’s a necessity. Companies that prioritize research and development (R&D) can gain significant advantages over their competitors. For instance, advancements in battery technology, such as the development of solid-state batteries, are revolutionizing the industry by offering higher energy densities and improved safety profiles. These innovations not only enhance product performance but also attract consumers who are increasingly eco-conscious and seeking sustainable solutions.

Another key area of innovation is the adoption of automation in manufacturing processes. By implementing automated systems, manufacturers can improve production efficiency, reduce labor costs, and maintain consistent quality. For example, robotics are now being used for tasks such as battery assembly and testing, allowing for faster turnaround times and increased output. This shift toward automation is essential as demand for lithium-ion batteries continues to surge, particularly in sectors like electric vehicles and renewable energy.

As we explore the innovations shaping this industry, it’s crucial for manufacturers to stay informed and agile. The next section will address the regulatory landscape that impacts battery production and compliance requirements that companies must navigate.

| Innovation Type | Impact on Manufacturing |

| Automation | Increased efficiency |

| New chemistries | Enhanced performance |

- Invest in automation

- Explore new materials

- Collaborate with R&D institutions

- "Innovation is the engine of progress in battery manufacturing."

Regulatory Landscape and Compliance

The regulatory landscape for lithium-ion battery manufacturing is complex and constantly evolving. Manufacturers must navigate a myriad of regulations that govern everything from safety standards to environmental impacts. Compliance with these regulations is crucial, as failure to adhere can result in significant penalties and damage to a company’s reputation. For instance, regulations regarding the safe handling and disposal of hazardous materials are particularly stringent and require manufacturers to implement rigorous safety protocols.

Moreover, manufacturers are increasingly held accountable for the sustainability of their production processes. This means that companies must not only focus on efficiency but also consider the environmental footprint of their operations. Adopting sustainable practices, such as using recycled materials and minimizing waste, can help manufacturers comply with regulations while also appealing to eco-conscious consumers.

Understanding and adapting to the regulatory environment is essential for companies looking to thrive in the lithium-ion battery market. As we transition to the next section, we will discuss the future outlook for battery manufacturing and the trends that will shape the industry moving forward.

| Regulation Type | Description |

| Safety Standards | Ensures product safety for consumers |

| Environmental Laws | Mandates sustainable production practices |

- Regularly review regulations

- Implement compliance training

- Engage with regulatory bodies

Future Outlook for Lithium-ion Battery Manufacturing

The future of lithium-ion battery manufacturing appears promising, with numerous opportunities for growth and innovation. Industry experts predict that the market will continue to expand, driven by increasing demand for electric vehicles, renewable energy storage solutions, and advancements in battery technology. As manufacturers invest in research and development, we can expect to see breakthroughs in battery performance, such as longer lifespans and faster charging times, which will further fuel market growth.

Another trend to watch is the rise of new entrants in the battery production sector. As the demand for batteries increases, startups and established companies alike are exploring opportunities to enter this lucrative market. This influx of competition will likely drive innovation and lower prices, benefiting consumers and businesses alike. Companies that are agile and willing to adapt to changing market conditions will be well-positioned to capitalize on these developments.

As we look ahead, it’s essential for manufacturers to remain vigilant and proactive in their strategies. By understanding market dynamics and embracing innovation, companies can secure their place in the future of the lithium-ion battery industry.

| Year | Expected Growth Rate |

| 2025 | 20% |

| 2030 | 15% |

- Stay informed about market trends

- Invest in technology

- Build strategic partnerships

Key Recommendations for Success

To thrive in the competitive landscape of lithium-ion battery manufacturing, companies must implement several key strategies. First and foremost, a focus on innovation is critical. Manufacturers should prioritize R&D to develop cutting-edge technologies that enhance battery performance and efficiency. This not only helps in meeting consumer demands but also sets the company apart from competitors.

Additionally, companies should be adaptable and responsive to market changes. By monitoring industry trends and consumer preferences, manufacturers can pivot their strategies as needed to capitalize on emerging opportunities. For instance, the growing emphasis on sustainability provides a chance for companies to enhance their green initiatives, which can be a significant differentiator in the market.

Finally, fostering collaboration and building strategic partnerships can lead to shared knowledge and resources, further driving innovation and growth. By working together with research institutions, suppliers, and even competitors, companies can strengthen their positions in the market.

| Strategy | Description |

| Innovation Focus | Prioritize R&D investment |

| Market Adaptability | Be responsive to market changes |

- Embrace innovation

- Monitor competition

- Enhance customer engagement

Future Strategies for Lithium-ion Battery Manufacturing

As the lithium-ion battery industry continues to evolve, manufacturers must adopt forward-thinking strategies to ensure long-term success. One critical approach is the integration of sustainable practices throughout the production process. This not only helps companies comply with increasing environmental regulations but also appeals to consumers who prioritize eco-friendly products. By focusing on sustainability, manufacturers can enhance their brand image and differentiate themselves in a crowded market.

Additionally, investing in advanced manufacturing technologies will be vital for enhancing efficiency and reducing costs. Techniques such as automation, artificial intelligence, and machine learning can streamline production processes and improve quality control. For instance, predictive maintenance powered by AI can minimize downtime and enhance productivity, ensuring that manufacturers can meet the growing demand for batteries without sacrificing quality.

Finally, fostering a culture of innovation within the organization can drive continuous improvement and adaptation to market changes. Encouraging employees to contribute ideas and collaborate on projects can lead to groundbreaking advancements and help maintain a competitive edge.

| Strategy | Description |

| Sustainability Focus | Integrate eco-friendly practices in production |

| Advanced Technologies | Invest in automation and AI |

- Enhance brand image through sustainability

- Streamline production with advanced technologies

- Encourage innovation within the organization

Practical Advice for Manufacturers

For manufacturers navigating the competitive landscape of lithium-ion battery production, practical advice can make a significant difference. First, focus on building strong relationships with suppliers to secure a reliable source of raw materials. Given the volatility of lithium and other essential components, having dependable partners can mitigate risks associated with supply chain disruptions.

Second, prioritize customer feedback and market research to align product offerings with consumer needs. By understanding what customers value most—be it performance, price, or sustainability—manufacturers can tailor their strategies to meet those demands effectively. Engaging with customers through surveys and focus groups can provide valuable insights that drive product development.

Lastly, consider investing in training and development programs for employees to foster a skilled workforce capable of adapting to new technologies and processes. A knowledgeable team is essential for implementing innovative strategies and maintaining high production standards.

- "Success comes to those who persevere."

- Build strong supplier relationships

- Focus on customer feedback

- Invest in employee training

Conclusion

In summary, the Lithium Ion Battery Manufacturing Competition Study highlights the importance of understanding the competitive landscape, embracing innovation, and navigating regulatory challenges in the battery production industry. As the market continues to grow, manufacturers must adapt their strategies to capitalize on emerging trends and overcome obstacles. By implementing the recommendations discussed in this article, companies can position themselves for success in this dynamic field.

For those looking to start or enhance their journey in the lithium-ion battery manufacturing sector, consider exploring our Lithium Ion Battery Manufacturing Business Plan Template. Additionally, check out these informative articles to deepen your understanding:

- SWOT Analysis for Lithium Ion Battery Manufacturing: Key Strategies

- Lithium Ion Battery Manufacturing Profitability: Key Considerations

- Writing a Business Plan for Lithium Ion Battery Manufacturing: Template Included

- Crafting a Financial Plan for Your Lithium Ion Battery Manufacturing Business: Essential Steps (+ Template)

- Building a Lithium Ion Battery Manufacturing Business: Comprehensive Guide

- Create a Marketing Plan for Your Lithium Ion Battery Manufacturing (+ Example)

- Building a Business Model Canvas for Lithium Ion Battery Manufacturing: A Comprehensive Guide

- How Much Does It Cost to Start a Lithium Ion Battery Manufacturing Business?

- How to Calculate the Feasibility Study for Lithium Ion Battery Manufacturing?

- How to Build a Risk Management Plan for Lithium Ion Battery Manufacturing?

- How to Navigate Legal Considerations in Lithium Ion Battery Manufacturing?

- What Funding Options Should You Consider for Lithium Ion Battery Manufacturing?

- Lithium Ion Battery Manufacturing Growth Strategies: Scaling Success Stories

FAQ

What are the main challenges in lithium-ion battery manufacturing?

Manufacturers often face challenges such as raw material sourcing, production efficiency, and maintaining regulatory compliance. These factors can significantly impact operational costs and product quality.

How can companies stay competitive in the lithium-ion battery market?

To remain competitive, companies should focus on innovation, invest in advanced manufacturing technologies, and adapt to changing market demands. Engaging in research and development is essential for driving advancements in battery technology.

What trends are shaping the lithium-ion battery industry?

Key trends include the increasing demand for electric vehicles, advancements in battery technology, and a growing focus on sustainability. These trends are influencing how manufacturers approach production and product development.

Why is regulatory compliance important in battery manufacturing?

Compliance with regulations ensures safety and minimizes risks associated with battery production. Manufacturers must adhere to environmental laws and safety standards to protect consumers and the environment.

What role does research and development play in battery manufacturing?

Research and development are crucial for driving innovation and improving product performance. Companies that invest in R&D are more likely to develop cutting-edge technologies that meet consumer demands.

How can manufacturers reduce production costs?

Manufacturers can reduce costs by optimizing their supply chains, investing in automation, and improving production processes to enhance efficiency.

What is the significance of automation in battery manufacturing?

Automation increases efficiency, reduces labor costs, and improves product quality. By implementing automated systems, manufacturers can streamline operations and meet the growing demand for lithium-ion batteries.

What is the expected growth rate for the lithium-ion battery market?

The lithium-ion battery market is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, driven by demand for electric vehicles and renewable energy solutions.

How can companies build strategic partnerships in the industry?

Building strategic partnerships involves collaborating with research institutions, suppliers, and even competitors to share knowledge and resources. This approach can lead to innovative solutions and strengthen market positions.

What are the future predictions for the lithium-ion battery market?

The future of the lithium-ion battery market looks bright, with continued growth expected as demand for energy storage solutions and electric vehicles rises. Companies that adapt to market trends and embrace innovation will thrive.