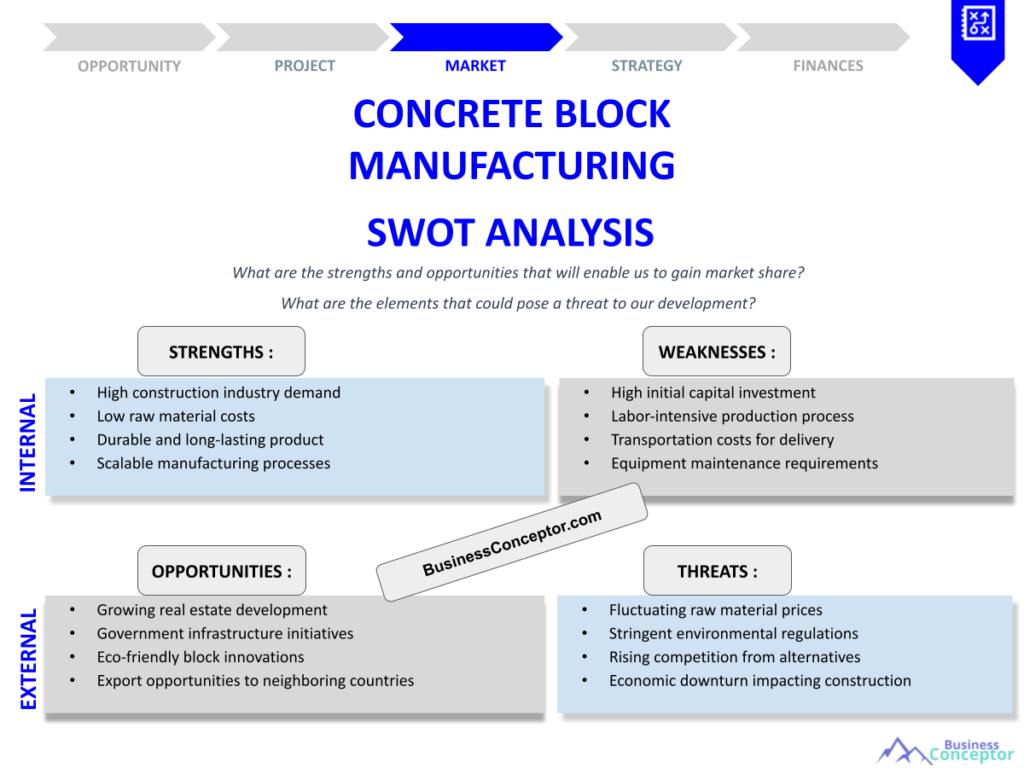

Did you know that concrete blocks are among the most widely utilized building materials globally, making up a significant portion of the construction industry? Concrete Block Manufacturing SWOT Analysis is crucial for understanding the dynamics of this industry. This analysis breaks down the strengths, weaknesses, opportunities, and threats that manufacturers face in a competitive market. By grasping these elements, stakeholders can make informed decisions that drive success and sustainability in concrete block production.

- Introduction to concrete block manufacturing

- Overview of SWOT analysis

- Importance of market insights

- Exploration of strengths in production

- Identification of weaknesses

- Opportunities for growth in the industry

- Threats impacting concrete manufacturing

- Actionable strategies for success

- Real-world examples and case studies

Understanding the Basics of Concrete Block Manufacturing

Concrete block manufacturing is a vital sector in the construction industry, known for producing durable and versatile building materials. The process involves mixing cement, aggregates, and water to create blocks that can be molded into various shapes and sizes. This section will delve into the core aspects of concrete block production, including raw materials and manufacturing techniques. Understanding these fundamentals is essential for conducting a thorough SWOT analysis.

For instance, the production process can vary significantly depending on the technology used—ranging from manual methods to fully automated systems. Companies often invest in advanced machinery to enhance efficiency and product quality. By examining these production methods, we can better appreciate the strengths that a company may leverage in a competitive market.

As we explore the intricacies of concrete block manufacturing, it becomes clear that understanding the production landscape sets the stage for a comprehensive SWOT analysis. This foundational knowledge leads us to examine the strengths of the concrete block manufacturing industry.

| Aspect | Details |

|---|---|

| Core Material | Cement, aggregates, water |

| Production Methods | Manual, semi-automated, automated |

- Concrete blocks are durable and versatile

- Manufacturing involves cement and aggregates

- Technology impacts efficiency and quality

- "Quality is not an act, it is a habit." – Aristotle

Strengths of Concrete Block Manufacturing

The strengths of concrete block manufacturing are numerous and play a pivotal role in the industry’s success. From cost-effectiveness to durability, these strengths contribute to the widespread adoption of concrete blocks in construction projects. This section will highlight these key advantages, illustrating why concrete blocks are a preferred choice among builders.

For example, concrete blocks are known for their thermal mass, which can improve energy efficiency in buildings. Moreover, they are fire-resistant and can withstand harsh weather conditions, making them suitable for a variety of climates. These attributes not only enhance the value of concrete blocks but also solidify their position in the market.

Recognizing these strengths is essential for manufacturers to capitalize on their competitive edge. As we transition to the next section, we will explore the weaknesses that can challenge the concrete block manufacturing process.

| Strength | Description |

|---|---|

| Cost-effective production | Affordable raw materials and low production costs |

| Durability and longevity | Long-lasting materials suitable for various applications |

- Cost-effective production - Durability and longevity - Energy efficiency benefits - Fire resistance - Versatile applications

- "To succeed, always move forward with a clear vision."

Weaknesses in Concrete Block Manufacturing

While there are many strengths, the concrete block manufacturing industry is not without its weaknesses. Understanding these vulnerabilities is crucial for manufacturers aiming to improve their operations and market presence. This section will discuss common weaknesses that can hinder success in the concrete block sector.

For instance, the reliance on raw materials can create challenges, especially when supply chain disruptions occur. Additionally, the environmental impact of concrete production has raised concerns, leading to increased regulatory scrutiny. These factors can pose significant risks to manufacturers if not managed properly.

By acknowledging these weaknesses, companies can devise strategies to mitigate risks and improve their processes. This awareness will lead us into a discussion of the opportunities available within the concrete block manufacturing landscape.

| Weakness | Description |

|---|---|

| Supply chain vulnerabilities | Dependence on specific suppliers can cause disruptions |

| Environmental impact concerns | Manufacturing processes may contribute to pollution |

- Supply chain vulnerabilities - Environmental impact concerns - Regulatory challenges

- "The only limit to our realization of tomorrow will be our doubts of today." – Franklin D. Roosevelt

Opportunities in Concrete Block Manufacturing

The concrete block manufacturing industry is ripe with opportunities for growth and innovation. As the construction landscape evolves, manufacturers can seize new trends and technologies to enhance their offerings. This section will outline the potential opportunities that can lead to market success.

For example, the increasing demand for sustainable building materials has led to a rise in eco-friendly concrete block production methods. Companies that adopt green practices can appeal to environmentally-conscious consumers, opening new market segments. Additionally, advancements in technology, such as 3D printing, present exciting avenues for product development.

Identifying and capitalizing on these opportunities can position manufacturers for long-term success. In the following section, we will examine the threats that the concrete block industry faces and how they can impact overall performance.

| Opportunity | Description |

|---|---|

| Sustainable practices | Eco-friendly production methods appealing to consumers |

| Technological advancements | Innovations like 3D printing for enhanced production |

- Explore sustainable production methods

- Invest in technology upgrades

- Target new market segments

- The above steps must be followed rigorously for optimal success.

Threats to Concrete Block Manufacturing

Despite the many opportunities, the concrete block manufacturing industry faces several threats that can undermine growth and profitability. Understanding these threats is essential for manufacturers looking to navigate challenges effectively. This section will delve into the various external factors that can pose risks to the industry.

Economic downturns, for instance, can lead to reduced construction activity, directly affecting demand for concrete blocks. Additionally, competition from alternative building materials, such as steel or timber, can also pose a threat. Manufacturers must remain vigilant to these challenges to ensure their market position.

By recognizing and addressing these threats, companies can develop proactive strategies to safeguard their interests. This awareness will lead us into the final sections, where we will summarize key points and encourage action.

| Threat | Impact |

|---|---|

| Economic downturns | Reduced demand for construction |

| Competition from alternatives | Loss of market share |

- Monitor economic indicators

- Differentiating from competitors

- Innovate to stay relevant

Strategies for Success in Concrete Block Manufacturing

To thrive in the concrete block manufacturing industry, companies must adopt effective strategies that leverage their strengths and mitigate weaknesses. This section will outline actionable strategies that can enhance market performance and drive success.

For instance, investing in technology can streamline production processes and reduce costs. By upgrading machinery and employing automation, manufacturers can increase efficiency and improve product quality. Additionally, focusing on customer relationships and feedback can help manufacturers align their products with market demands, ensuring they meet the needs of builders and contractors.

These strategies create a competitive advantage that can lead to increased sales and market presence. As we wrap up, we’ll summarize the key insights from our SWOT analysis and encourage manufacturers to take actionable steps toward success.

| Strategy | Description |

|---|---|

| Technology investment | Streamline processes and reduce costs |

| Customer engagement | Align products with market demands |

- Invest in new technologies

- Build strong customer relationships

- Continuously innovate products

- Implementing these strategies will lead to sustainable growth.

Future Trends in Concrete Block Manufacturing

The future of concrete block manufacturing is shaped by emerging trends that reflect changing market demands and technological advancements. As the construction industry evolves, manufacturers must adapt to these trends to remain competitive. This section will explore the key future trends impacting the concrete block sector.

One significant trend is the increasing emphasis on sustainability. Consumers and builders are more environmentally conscious than ever, pushing manufacturers to adopt eco-friendly practices. This includes using recycled materials in concrete block production and reducing carbon emissions during manufacturing. Additionally, innovations such as lightweight concrete blocks are gaining popularity due to their lower environmental impact and improved energy efficiency.

Another trend is the integration of smart technology into manufacturing processes. Automation and data analytics can enhance production efficiency, reduce waste, and improve product quality. Manufacturers who embrace these technologies will not only streamline operations but also position themselves as leaders in the evolving market. As we move towards the conclusion, it’s essential to understand the critical aspects of implementing these trends effectively.

| Trend | Description |

|---|---|

| Sustainability | Adoption of eco-friendly practices and materials |

| Smart technology | Use of automation and data analytics in production |

- Invest in sustainable materials

- Implement smart manufacturing technologies

- Stay informed about market trends

- Embracing these trends will lead to long-term success.

Key Recommendations for Concrete Block Manufacturers

As we summarize the insights from our SWOT analysis of the concrete block manufacturing industry, several key recommendations emerge for manufacturers seeking to improve their operations and market position. This section will highlight actionable steps that can enhance productivity and profitability.

First and foremost, manufacturers should prioritize investing in technology. Upgrading machinery and incorporating automation can significantly increase production efficiency and reduce operational costs. Additionally, fostering strong relationships with customers through feedback and engagement will ensure that products meet market demands, ultimately leading to higher sales.

Moreover, manufacturers should actively seek to innovate their product offerings. By exploring new designs and sustainable materials, companies can differentiate themselves from competitors and attract environmentally-conscious consumers. These recommendations, when implemented, will position manufacturers for success in the ever-changing landscape of concrete block production.

| Recommendation | Description |

|---|---|

| Invest in technology | Upgrade machinery for improved efficiency |

| Foster customer relationships | Engage customers for feedback and product alignment |

- Explore innovative product designs

- Utilize sustainable materials

- Differentiation to attract consumers

Conclusion

In conclusion, the concrete block manufacturing industry offers a wealth of opportunities and challenges that require careful navigation. By conducting a thorough SWOT analysis, manufacturers can identify their strengths, recognize weaknesses, seize opportunities, and address threats. Emphasizing sustainability, investing in technology, and fostering customer relationships are essential strategies for achieving long-term success.

For those looking to establish or enhance their business in this industry, consider utilizing a comprehensive Concrete Block Manufacturing Business Plan Template to guide your efforts. Additionally, you might find the following articles helpful:

- Article 1: Concrete Block Manufacturing Profitability: Tips for Financial Success

- Article 2: Crafting a Business Plan for Your Concrete Block Manufacturing: Step-by-Step Guide

- Article 3: How to Create a Financial Plan for Your Concrete Block Manufacturing Business: Step-by-Step Guide (+ Template)

- Article 4: Starting a Concrete Block Manufacturing Business: A Detailed Guide

- Article 5: Building a Concrete Block Manufacturing Marketing Plan: Strategies and Example

- Article 6: Crafting a Business Model Canvas for Concrete Block Manufacturing: Tips and Examples

- Article 7: Customer Segments in Concrete Block Manufacturing: Who Are Your Target Audiences?

- Article 8: How Much Does It Cost to Start a Concrete Block Manufacturing Business?

- Article 9: Concrete Block Manufacturing Feasibility Study: Essential Guide

- Article 10: Concrete Block Manufacturing Risk Management: Essential Guide

- Article 11: Concrete Block Manufacturing Competition Study: Expert Tips

- Article 12: Concrete Block Manufacturing Legal Considerations: Ultimate Guide

- Article 13: Concrete Block Manufacturing Funding Options: Ultimate Guide

- Article 14: Concrete Block Manufacturing Growth Strategies: Scaling Success Stories

FAQ Section

What is concrete block manufacturing?

Concrete block manufacturing involves producing blocks made from a mixture of cement, aggregates, and water, used widely in construction.

What are the strengths of concrete block manufacturing?

Strengths include cost-effectiveness, durability, and energy efficiency, making them ideal for various building applications.

What weaknesses exist in concrete block production?

Common weaknesses include reliance on raw materials and environmental impact concerns, which can affect sustainability efforts.

What opportunities can manufacturers explore?

Opportunities include adopting sustainable practices and leveraging technological advancements to improve production efficiency.

What threats does the concrete block industry face?

Threats include economic downturns and competition from alternative building materials, which can impact market share.

How can companies improve their concrete block manufacturing?

Companies can improve by investing in technology and engaging with customers to align products with market demands.

What role does sustainability play in concrete manufacturing?

Sustainability is crucial as it meets the growing demand for eco-friendly building materials, enhancing the market appeal of concrete blocks.

How does technology impact concrete block production?

Technology enhances efficiency, reduces costs, and improves product quality through automation and advanced manufacturing techniques.

What are the best practices for marketing concrete blocks?

Best practices include targeting specific market segments and highlighting the benefits of concrete blocks to attract potential customers.

How can manufacturers mitigate risks in concrete production?

Manufacturers can mitigate risks by diversifying supply chains and adapting to market changes to remain competitive.