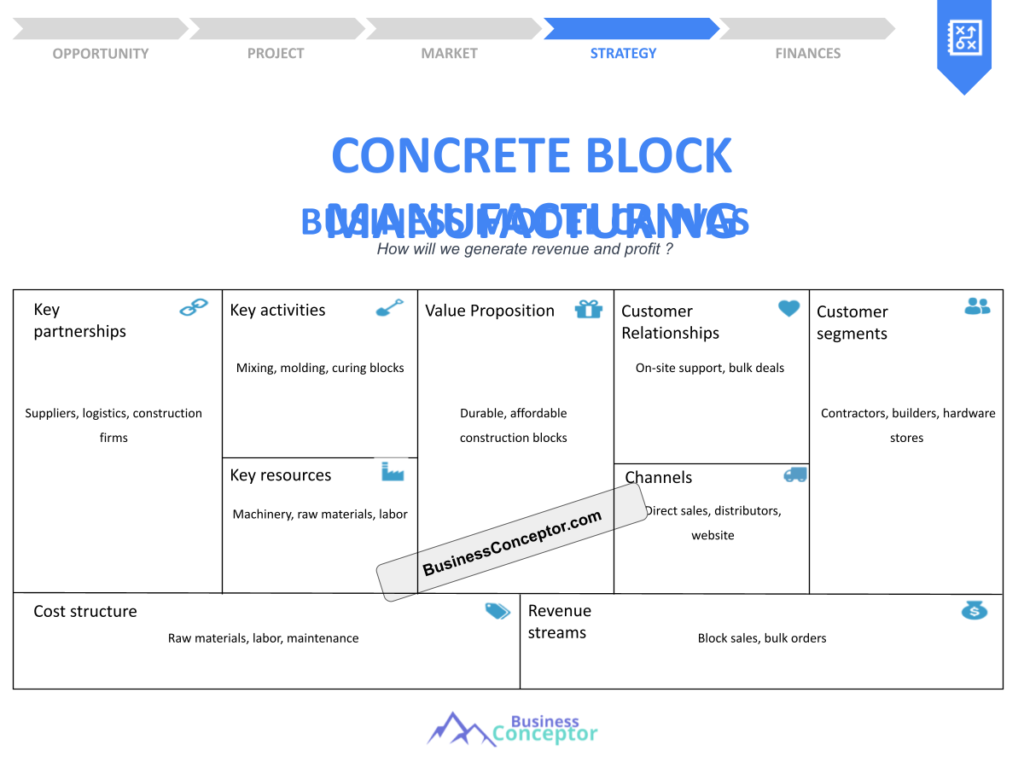

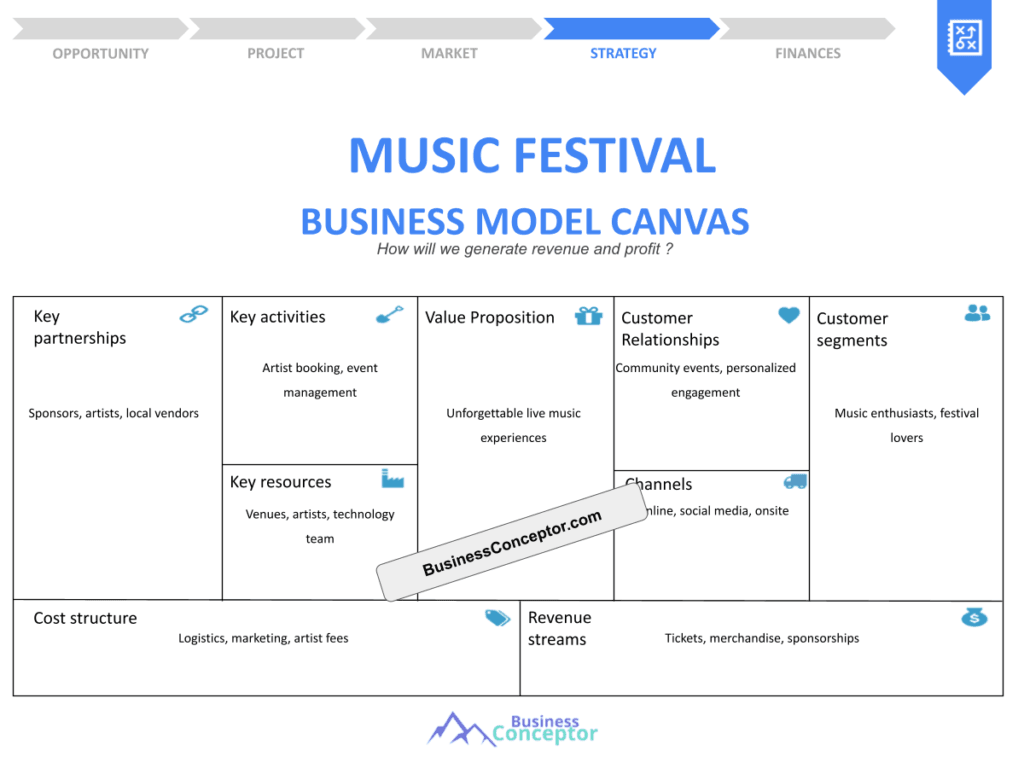

Did you know that the concrete block industry is projected to grow significantly, driven by the increasing demand for sustainable building materials? The Concrete Block Manufacturing Business Model Canvas is not just a buzzword; it’s a vital tool for anyone looking to thrive in this competitive market. A business model canvas helps you visualize and strategize all aspects of your business, from production to customer relations. This visual representation breaks down your business into key elements, making it easier to understand and manage.

- Understand the importance of a business model canvas.

- Learn about key components of concrete block manufacturing.

- Explore customer segmentation strategies.

- Discover operational efficiency tips.

- Analyze revenue streams and cost structures.

- Examine marketing strategies tailored for the industry.

- Get insights into supply chain management.

- Evaluate sustainability practices in production.

- Learn from real-life examples and case studies.

- Understand how to adapt your model for future growth.

The Importance of a Business Model Canvas in Concrete Block Manufacturing

A business model canvas is a strategic tool that helps visualize the components of a business. In concrete block manufacturing, it serves as a roadmap, guiding you through the complexities of production and sales. This visual representation breaks down your business into key elements, making it easier to understand and manage.

For instance, when developing your business model, consider customer segments that are most likely to purchase concrete blocks, such as construction companies or DIY homeowners. Understanding your audience will help shape your marketing and sales strategies effectively.

Ultimately, a well-structured business model canvas not only clarifies your operational processes but also sets the stage for growth and adaptability in a changing market.

| Key Component | Description |

|---|---|

| Customer Segments | Target groups for your concrete blocks |

| Value Proposition | Unique benefits your product offers |

- Clear visualization of business elements

- Helps identify target customers

- Supports strategic planning…

- "A goal without a plan is just a wish."

Key Components of Concrete Block Manufacturing

Understanding the components of concrete block manufacturing is crucial for creating an effective business model. Key elements include raw materials, production processes, and quality control measures. These components play a vital role in ensuring that your business runs smoothly and efficiently.

For example, a significant portion of manufacturing costs comes from raw materials. By analyzing your supply chain and seeking reliable suppliers, you can reduce costs and improve your profit margins. Effective cost analysis helps you identify where savings can be made without compromising on quality.

Integrating quality control at every stage of production ensures that your concrete blocks meet industry standards and customer expectations. This focus on quality is vital for maintaining a competitive edge and fostering customer loyalty.

| Key Component | Description |

|---|---|

| Raw Materials | Essential materials for producing concrete blocks |

| Production Processes | Steps involved in creating concrete blocks |

- Identify the right suppliers for raw materials

- Implement quality control measures

- Optimize production efficiency…

- "Success is where preparation and opportunity meet."

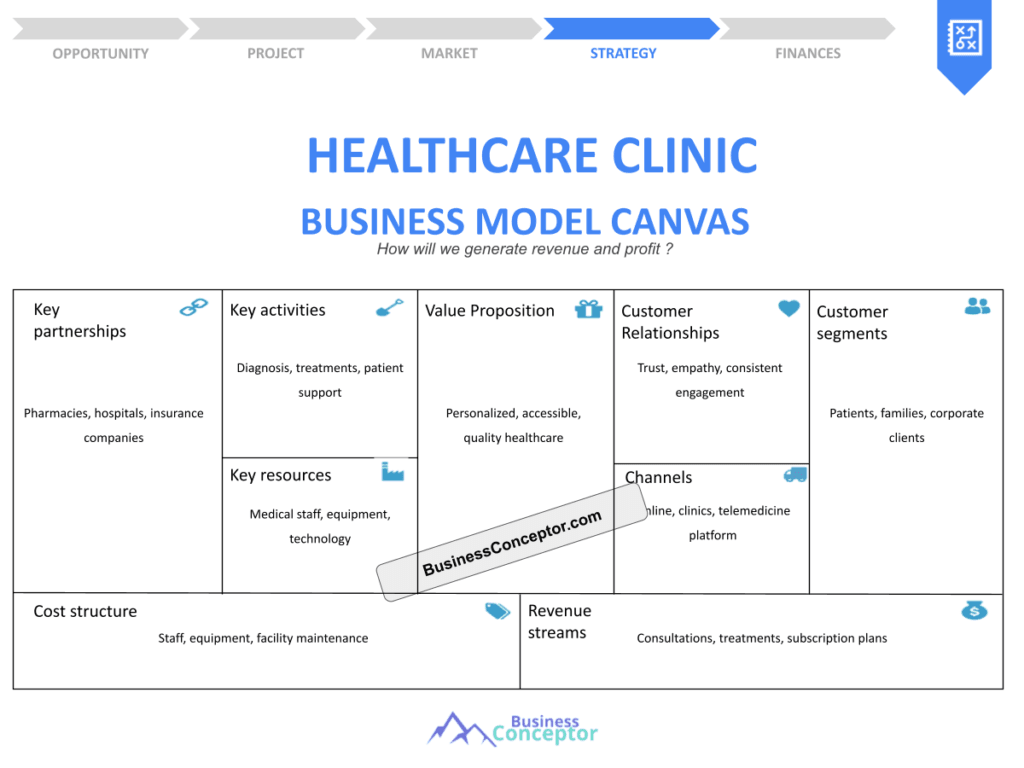

Analyzing Customer Segments

Identifying customer segments is another critical aspect of your business model. Different segments may have varying needs and preferences, which can affect your marketing strategies. Understanding these segments will help you tailor your offerings to meet their specific demands.

For instance, a construction company may prioritize bulk purchases at competitive rates, while a homeowner might look for customization options. Tailoring your offerings can significantly enhance customer satisfaction and drive sales.

By understanding your customer segments, you can create targeted marketing campaigns that resonate with each group, increasing your chances of conversion. This approach not only boosts sales but also fosters long-term relationships with your clients.

- Segment customers based on needs

- Tailor offerings for each segment

- Increase satisfaction through customization…

- "Know your audience to serve them better."

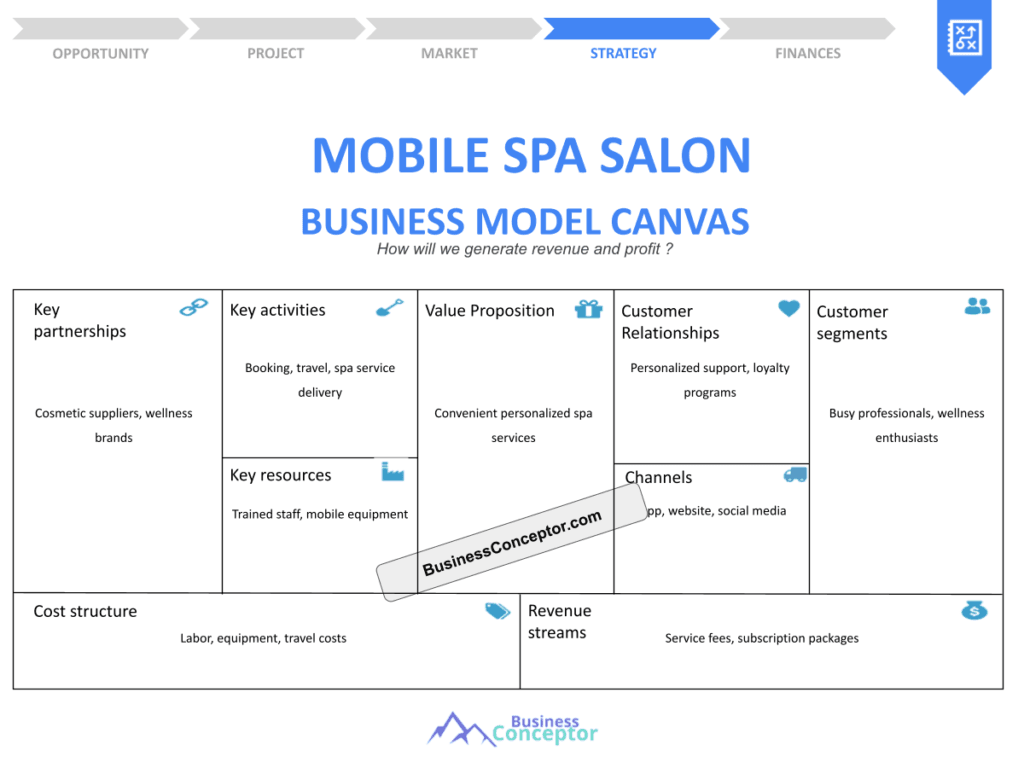

Operational Efficiency in Production

Operational efficiency is key in the concrete block manufacturing industry. Streamlining production processes can lead to significant cost savings and improved product quality. By focusing on efficiency, you can maximize your output while minimizing waste.

Implementing lean manufacturing principles can help reduce waste and optimize your production line. For instance, organizing workstations to minimize movement can enhance productivity. Additionally, using technology to automate certain tasks can further improve efficiency, allowing your workforce to focus on higher-value activities.

Efficient operations not only improve your bottom line but also allow for quicker response times to market demands. By continuously monitoring and refining your processes, you can stay ahead of the competition and better serve your customers.

| Operational Strategy | Benefits |

|---|---|

| Lean Manufacturing | Reduces waste and costs |

- Analyze production processes

- Implement lean principles

- Monitor efficiency metrics…

- "Efficiency is doing better what is already being done."

Marketing Strategies for Concrete Blocks

Marketing strategies are vital for attracting customers in the concrete block manufacturing industry. Understanding your target market allows you to craft compelling messages that resonate with potential buyers. A well-thought-out marketing approach can significantly impact your sales and brand reputation.

Utilizing digital marketing channels, such as social media and SEO, can enhance your visibility and reach. Engaging content that showcases your products, including videos and testimonials, can draw in potential clients. Additionally, attending industry trade shows can provide networking opportunities and increase brand awareness.

Incorporating customer testimonials and case studies into your marketing can build trust and credibility, encouraging prospects to choose your concrete blocks over competitors. By showcasing your successes and satisfied customers, you can create a compelling narrative that attracts new business.

| Marketing Channel | Description |

|---|---|

| Social Media | Engage with potential customers |

- Develop a marketing plan

- Utilize digital channels

- Gather customer testimonials…

Sustainability Practices in Concrete Block Manufacturing

Sustainability is becoming increasingly important in manufacturing. Implementing eco-friendly practices in your concrete block manufacturing business can enhance your brand image and appeal to environmentally conscious consumers. By focusing on sustainability, you not only contribute to a healthier planet but also tap into a growing market segment.

For example, using recycled materials in your concrete blocks can reduce environmental impact and lower material costs. This practice not only benefits the planet but can also attract customers who prioritize sustainability in their purchasing decisions. Additionally, optimizing energy use during production can further enhance your sustainability profile.

By adopting sustainable practices, you position your business as a leader in responsible manufacturing, which can lead to increased customer loyalty and long-term success. Customers are more likely to support companies that demonstrate a commitment to the environment, which can significantly impact your bottom line.

| Sustainability Practice | Benefits |

|---|---|

| Recycling Materials | Reduces costs and environmental impact |

- Evaluate current practices

- Research sustainable materials

- Market eco-friendly products…

- "Sustainability is not a choice; it is a responsibility."

Financial Projections for Growth

Financial projections are essential for planning your concrete block manufacturing business. Accurate forecasting helps you identify potential challenges and opportunities for growth. By understanding your financial landscape, you can make informed decisions that drive your business forward.

Consider factors such as market demand, production costs, and pricing strategies when creating your financial projections. This data-driven approach will guide your decision-making process and help you allocate resources effectively. Regularly updating your projections based on real-time data will ensure your business remains agile and competitive.

Additionally, having a clear understanding of your financial goals allows you to set realistic targets and measure your progress over time. This proactive approach to financial management can significantly enhance your chances of long-term success in the concrete block industry.

| Financial Metric | Importance |

|---|---|

| Cost Analysis | Determines pricing and profitability |

- Create detailed financial projections

- Analyze market trends

- Adjust forecasts regularly…

Real-Life Examples of Successful Models

Looking at real-life examples of successful concrete block manufacturers can provide valuable insights. These case studies highlight best practices and strategies that have led to success in the concrete block manufacturing industry. By examining these models, you can identify effective approaches that may work for your own business.

For instance, one company focused on customization and customer service saw significant growth in its client base. Their approach of engaging customers in the design process created a unique selling proposition that set them apart from competitors. By prioritizing customer needs, they built a loyal following and increased their market share.

Learning from these examples can help you identify strategies that align with your business goals. Adaptation and innovation based on proven successes can lead to greater efficiency and profitability in your own operations.

| Case Study | Key Takeaway |

|---|---|

| Customization Focus | Engaging customers enhances satisfaction |

- Research successful case studies

- Identify applicable strategies

- Adapt to your business model…

- "Success is not just about what you accomplish, but what you inspire others to do."

Challenges and Solutions in Concrete Block Manufacturing

Every business faces challenges, and concrete block manufacturing is no exception. Identifying these challenges early can help you devise effective solutions that keep your operations running smoothly. Common issues include supply chain disruptions, fluctuating material costs, and increasing competition.

By being proactive and developing contingency plans, you can mitigate these risks. For example, establishing relationships with multiple suppliers can provide alternatives in case of disruptions. Additionally, monitoring market trends and adjusting your pricing strategies can help you stay competitive despite rising costs.

Staying informed about industry trends and consumer preferences can also help you navigate challenges and maintain a competitive edge. By adapting your business strategies to meet changing demands, you can ensure long-term success in the concrete block industry.

| Challenge | Solution |

|---|---|

| Supply Chain Disruptions | Diversify suppliers to reduce risk |

- Identify potential challenges

- Develop contingency plans

- Stay informed about industry trends…

Conclusion

In summary, crafting a Concrete Block Manufacturing Business Model Canvas involves understanding key components such as customer segments, operational efficiency, and marketing strategies. By focusing on sustainability and financial projections, you can position your business for long-term success. For those looking to take their planning to the next level, consider using the Concrete Block Manufacturing Business Plan Template to streamline your efforts.

Additionally, you may find our other articles on Concrete Block Manufacturing useful:

- SWOT Analysis for Concrete Block Manufacturing: Achieving Market Success

- Concrete Block Manufacturing Profitability: Tips for Financial Success

- Crafting a Business Plan for Your Concrete Block Manufacturing: Step-by-Step Guide

- How to Create a Financial Plan for Your Concrete Block Manufacturing Business: Step-by-Step Guide (+ Template)

- Starting a Concrete Block Manufacturing Business: A Detailed Guide

- Building a Concrete Block Manufacturing Marketing Plan: Strategies and Example

- Customer Segments in Concrete Block Manufacturing: Who Are Your Target Audiences?

- How Much Does It Cost to Start a Concrete Block Manufacturing Business?

- Concrete Block Manufacturing Feasibility Study: Essential Guide

- Concrete Block Manufacturing Risk Management: Essential Guide

- Concrete Block Manufacturing Competition Study: Expert Tips

- Concrete Block Manufacturing Legal Considerations: Ultimate Guide

- Concrete Block Manufacturing Funding Options: Ultimate Guide

- Concrete Block Manufacturing Growth Strategies: Scaling Success Stories

FAQ

What is a business model canvas?

A business model canvas is a strategic tool that visually outlines the key components of a business, helping to clarify operations and strategy.

How can I improve operational efficiency in concrete block manufacturing?

Implementing lean manufacturing principles and optimizing production processes can enhance operational efficiency.

What are the key customer segments in concrete block manufacturing?

Key customer segments include construction companies, architects, and homeowners.

Why is sustainability important in manufacturing?

Sustainability improves brand image, attracts eco-conscious consumers, and reduces environmental impact.

How do I create financial projections for my concrete block business?

Analyze market demand, production costs, and pricing strategies to develop accurate financial projections.

What marketing strategies are effective for concrete blocks?

Utilizing digital marketing, engaging content, and customer testimonials can effectively attract customers.

How can I differentiate my concrete blocks from competitors?

Offering customization options and superior customer service can help you stand out in the market.

What are common challenges in concrete block manufacturing?

Common challenges include supply chain disruptions, fluctuating material costs, and increasing competition.

How can I ensure quality control in production?

Implementing quality control measures at every stage of production can maintain high standards.

What are the benefits of using recycled materials in concrete blocks?

Using recycled materials can lower costs and reduce environmental impact, appealing to sustainability-focused consumers.